The injection molding industry is changing fast, thanks to new software technology. THY Precision leads this change by using software to make their machines better. But what exactly does software do in this industry? How does it change how THY Precision injection molding machine types work and change manufacturing?

THY Precision is always looking to improve. They use software with their machines, like hydraulic, electric, and hybrid ones. They also use vertical, horizontal, insert, overmolding, and multi-component machines. This mix of software and machines makes THY Precision’s processes more precise, efficient, and high-quality.

Key Takeaways

- Software is key to making injection molding machine types better, improving precision and efficiency.

- THY Precision is leading the way in adding software to their machines, including many types.

- Software changes how machines work, from simple to complex ones, making them better.

- With software, THY Precision gets amazing performance and reliability in their processes.

- Combining software with machines is changing manufacturing, starting a new era of smart, data-driven injection molding.

Understanding Injection Molding and Its Machinery

Injection molding is a key process in many industries, from cars to everyday items. It turns raw materials, usually plastic, into complex shapes. Knowing how this process works is key to making it work well.

The Basics of Injection Molding

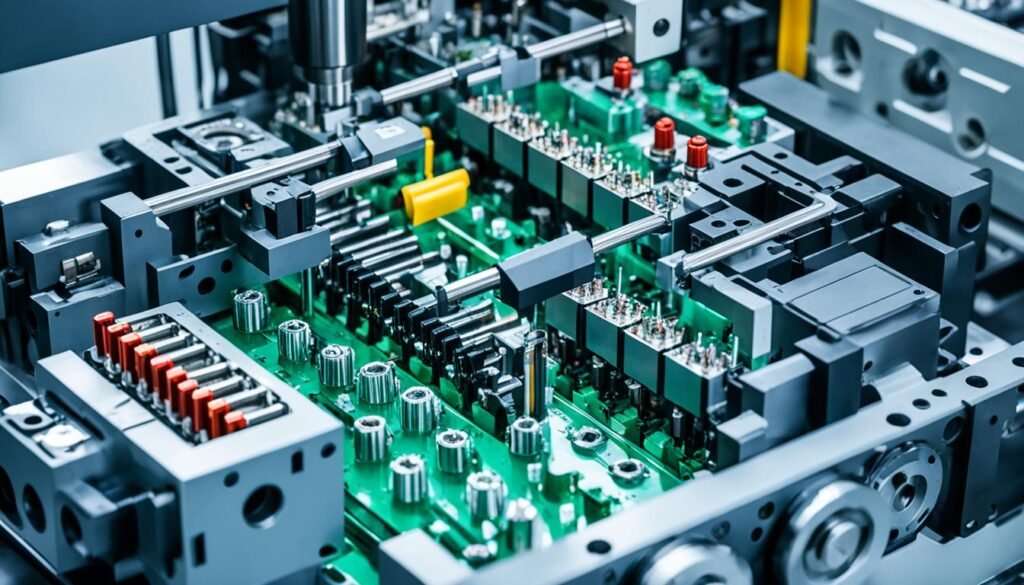

The process starts with a few steps that need both skill and modern tech. At the heart is the injection molding machine types. It has parts like the hopper, barrel, screw, and mold cavity. Each part is crucial for making the process work right.

The Injection Molding Machine

The first step is melting the raw material in the barrel. Then, the melted material gets pushed into the mold at high pressure. This step is important for the product’s quality.

Material Melting and Injection

After the material is in the mold, it must cool fast to set. The cooling process is watched closely to avoid mistakes. This step is key for a quality product.

Cooling and Solidification

Once the product is set, it comes out of the mold. Then, it’s checked for quality and standards. This final check is vital for top-notch products.

Ejection and Final Inspection

Knowing the parts and steps of the injection molding process helps makers improve their work. This knowledge lets them use new tech and software to make their process better.

Software’s Crucial Role in Injection Molding

In today’s fast-paced manufacturing world, software has changed the game. It’s now key to how industries like injection molding work. At THY Precision, we see software as vital for making our injection molding machine types work better.

Software boosts precision and efficiency and helps with quality control. It’s now a must-have in injection molding. With software for injection molding, we can achieve results our clients love.

THY Precision uses software to improve every step of the injection molding process. We use data and automation to make our injection molding machine types work better. This means more productivity and less downtime.

Our software lets us watch the process closely and make changes on the fly. It also helps us check quality thoroughly. This makes sure our injection molding machine types are top-notch, keeping us leaders in the field.

“Software has become the backbone of our injection molding operations, allowing us to push the boundaries of what’s possible and deliver unparalleled results for our clients.”

At THY Precision, we’re always finding new ways to use software for injection molding. This keeps our injection molding machine types leading in innovation. By using software in all we do, we’re changing how injection molding is done. We set high standards that others try to follow.

Improvingprecisionandefficiencywithinjectmouldingmachinetypes

At THY Precision, we know that the secret to great injection molding machine types is in being precise and efficient. We use advanced software to make our injection molding solutions top-notch. This changes the game in how things are made.

Precision through Data-Driven Control

Our injection molding machine types come with smart software for total control. We manage temperature, pressure, and cooling times with precision. This means every product is perfect, every time. It cuts down on waste and keeps quality high.

Efficient Resource Utilization

At THY Precision, we aim to use resources wisely in injection molding machine types. Our software helps figure out just the right amount of material needed. This cuts down on waste and saves money. Plus, our systems use less energy and machines run better, making production greener and cheaper.

Reduced Downtime

Less downtime is key in injection molding machine types, and we’re all about it. Our software watches over things in real-time, catching problems fast. This means we can fix things right away, keeping production smooth.

By adding software to our injection molding machine types, THY Precision brings unmatched precision, efficiency, and reliability. See how data-driven control, smart resource use, and less downtime change the game with our leading solutions.

Streamlining Quality Control for Injection Molding Machine Types

For companies like THY Precision, keeping quality consistent in injection molding is key. They use software to check quality early and keep it steady. This is crucial for meeting the high standards customers expect from injection molding machine types.

Early Defect Detection

Advanced sensors and algorithms in injection molding machine types software spot problems right away. They start fixing issues fast. This keeps products top-notch and saves time and money. Early defect detection changes the game in quality control for injection molding.

Consistency Across Production Runs

Keeping quality the same across many products is tough. But, injection molding machine types with software keep the process steady. This means every product is just as good, from the first to the last. It gives THY Precision reliable and steady results.

“Software is the unsung hero of modern injection molding, ensuring that every part meets our exacting quality standards.”

THY Precision uses software to make quality control smoother for their injection molding machine types. This leads to high-quality products for their customers. Their focus on quality is a big reason for their success.

Injection Molding Machine Types and Software Integration

At THY Precision, we know how important it is to blend software with our injection molding machine types. We use software to make each machine work better, whether it’s hydraulic, electric, hybrid, or vertical. This integration of software in injection molding helps us meet our customers’ specific needs, giving them top-notch results.

We’re always pushing for innovation in injection molding machine types and software. By updating our software, we make sure our machines have the newest tech. This helps our clients lead the market.

| Injection Molding Machine Type | Software Integration Capabilities |

|---|---|

| Hydraulic Machines | Precise control over injection speed, pressure, and temperature; enhanced energy efficiency |

| Electric Machines | Improved repeatability, reduced energy consumption, and quieter operation |

| Hybrid Machines | Combination of hydraulic and electric technologies for optimal performance and cost-effectiveness |

| Vertical Machines | Specialized software for part handling, mold insert loading, and enhanced productivity |

THY Precision combines software with our wide range of injection molding machine types to give our customers the best results. This mix of advanced machines and software helps our clients make high-quality parts, cut down on downtime, and boost their manufacturing efficiency.

“At THY Precision, we are committed to providing our clients with the most innovative and technologically advanced injection molding solutions. Our software-driven approach to injection molding machine types is a testament to our dedication to excellence.”

As the industry changes, THY Precision stays ahead by always investing in new tech. We make sure our customers get the latest and most efficient tools. This lets them stay competitive and meet the market’s changing needs.

The Future of Software-Optimized Injection Molding

Technology is changing fast, and so is the future of injection molding machines. THY Precision is leading this change with new software solutions. They are always finding new ways to make their machines better.

THY Precision uses data and real-time monitoring to lead the way in manufacturing. They aim to give their customers the best precision, efficiency, and quality.

At the core of THY Precision’s vision is advanced software. They use smart algorithms and machine learning to make the molding process better. This includes everything from melting materials to inspecting the final product.

THY Precision focuses on using data to control the molding process. This means they can make sure every product is made just right. It leads to better quality products, less waste, and less downtime.

They also invest in simulation technology. This lets them test new ideas without making real prototypes. It’s a way to keep improving without wasting resources.

As injection molding evolves, THY Precision’s focus on software will be key. They blend new technology with their molding expertise. This will set new standards for making things.

“At THY Precision, we are not just building injection molding machine types – we are crafting the future of manufacturing excellence.”

Conclusion

In the fast-changing world of manufacturing, software is key for injection molding machine types. THY Precision leads by using the latest software to improve its injection molding machine types. This approach helps customers reach new levels in precision, efficiency, and quality control.

THY Precision stays ahead by focusing on software. It uses software in all its injection molding machine types. This lets the company offer top-notch manufacturing solutions that meet clients’ needs. It has changed how the industry looks at injection molding machine types with its software-optimized approach.

The future of manufacturing will highlight the importance of software in injection molding even more. THY Precision is a leader thanks to its focus on innovation and software. By using software in all its injection molding machine types, THY Precision is ready to lead in offering advanced manufacturing solutions. These solutions will drive progress and success for its customers.